Higher efficiency, accuracy, and economic benefits have been a company’s long-lasting business goals for ages, resulting in the rise of robotics and automation. However, creating new business models, maintaining reliability, and improving decision-making are still major concerns.

Create a 360° representation of your end-to-end product lifecycle, assess its behavior with what-if questions, and empower your organization to increase safety, consistency, and profitability.

By 2023, Digital Twin market will grow at a CAGR of 37.87%, meaning its market will reach to 15.66 billion USD.

– MarketsandMarkets

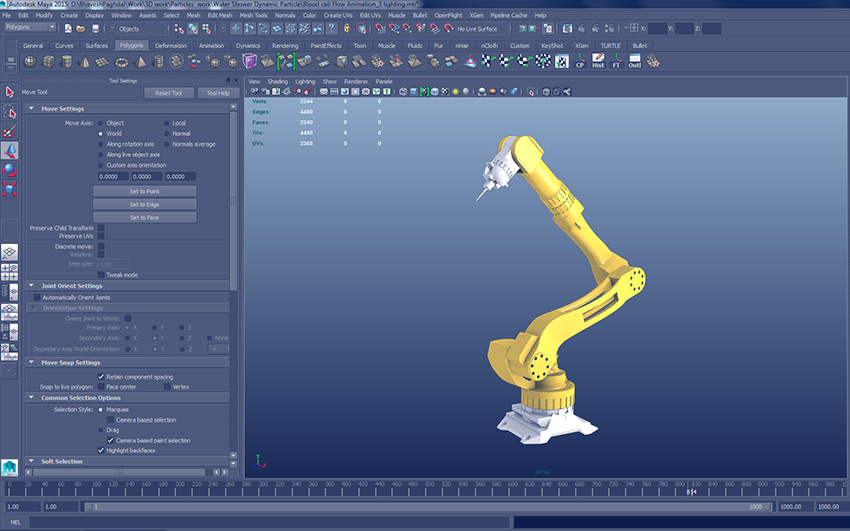

Whether you use CAD systems for creating 3D models, MCAD tools for electronic design, or CAE systems for analysis – everything can be connected and virtually designed, validated, and tested. The payoffs are: reduced development time, improved quality, and quicker response to customer feedback with faster iterations.

Test how your product, with all its components and sub-assemblies, will be built using manufacturing processes and automation. You can also identify the cause of production problems such as production line faults, plant inaccuracies, or supplier mistakes, thus increasing uptime and productivity.

We understand that ensuring model’s successful deployment and ongoing use is critical to your business’s success. Hence, our services extend beyond the initial design and development of your digital twin model. We are committed to providing comprehensive after-sales support and troubleshooting, including step-by-step instructions for quick and efficient repairs.

We are one of the leading real-time simulation technology providers. We help enterprises to develop a digital twin which meets their specific business needs throughout the product lifecycle. The process includes creating model-based simulations and applying data analytics at all stages. It helps to predict the outcome, optimize, correct, and evaluate the product quality and manufacturing process.