Customer Background

TMF Center is a manufacturing company based in rural, west-central Indiana that manufactures components for off-highway construction equipment, mining, and heavy-duty trucking industries. They have a second plant that specializes in high-volume component manufacturing. Their approach to competing on a global scale relies on utilizing cutting-edge technology and efficient manufacturing techniques within a business-friendly environment. They are committed to providing high-quality, competitively priced products manufactured consistently on time.

-

Industry

Manufacturing

-

Technologies / Platforms / Frameworks

HoloLens 2, Unity3D

Challenges

TMF Center manufactures parts for heavy-duty equipment that requires a lot of assembly and welding work. Their priority is to build high-quality products. They test each weld and certify each welding machine. Once the parameters for a particular weld are certified, all welds within the company are performed with the same parameters.

They encountered difficulties in providing real-time, step-by-step guidance to their employees and trainees as they engaged in welding heavy machinery parts within the production unit. The welding work requires high accuracy and precision up to 1-2mm to design the desired product. Also, the nature of client’s work is such that they do not always have internet access; hence, they needed an MR headset to fetch information from a physical device offline.

To sum up, there were three major challenges to overcome:

- Required precision up to 1-2mm

- Needed MR guide to fetch real-time changes

- 3D model to be precisely aligned with the real model

Solutions

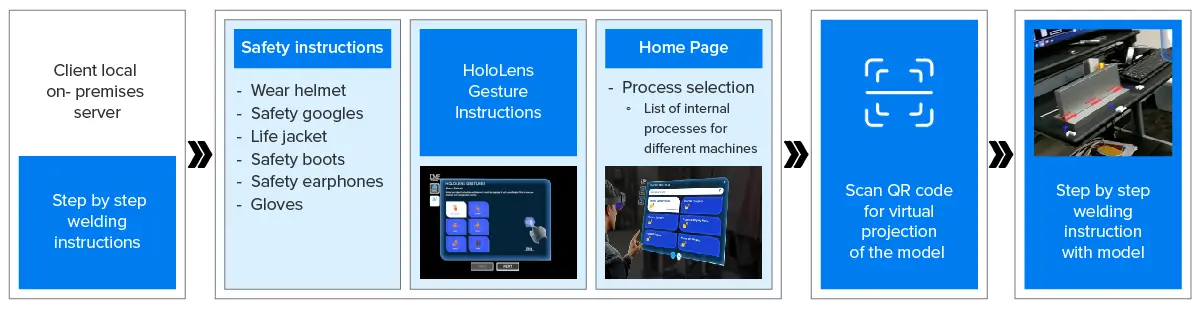

Upon gaining a thorough understanding of the client’s needs and challenges, our team collaborated to develop innovative solutions. Our initial approach was to establish an on-premises server to facilitate offline access and navigation of the file directory. This solution eliminates the need to depend on internet access for information retrieval and also simplifies the process of updating the physical system with any new changes.

Our team of mixed reality (MR) experts developed a user-friendly navigation system for the HoloLens 2 headset. This system enables technicians to easily browse directories, select relevant models, and retrieve information. The application provides clear and concise instructions, as well as specifies the tools and steps required, for each process. This helps technicians to understand and complete their tasks more efficiently and effectively.

We prioritized a user-friendly and intuitive design for the application, filtering out unnecessary components to streamline the user experience.

To project a 3D model in the desired space, we implemented a QR-based solution that allows workers to simply scan a QR code to overlay the 3D content on equipment. We also designed a 3D joystick/control panel for precise orientation and manipulation of the 3D model.

Finally, we added an FTP connection to help them save videos and images, enabling technicians to record their work progress and improve productivity. Stakeholders can also access this information to enhance transparency and collaboration.

Benefits

- Reduced costs associated with errors and rework

- Improved employee satisfaction and retention

- Increased transparency and stakeholder engagement

- Improved operational efficiency

- Zero dependency on internet access

Need more information?

Tell us what you are looking for and we will get back to you right away!