Customer Background

The client is a leading automobile manufacturer based in the United States of America. They have their presence in more than 20 countries. They produce a wide range of vehicles, from sedans to SUVs, serving to different market segments. With a large number of production facilities, their supply chain complexity is extensive, connecting multiple suppliers, logistics partners, and distribution channels.

-

Industry

Automobile, Supply chain

-

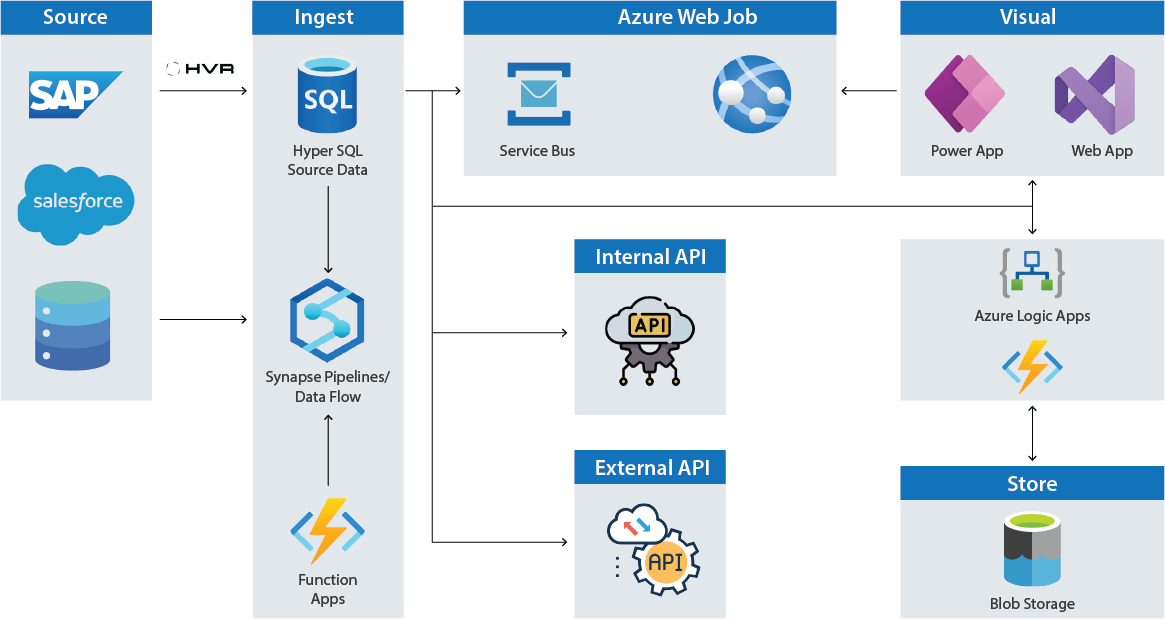

Technologies / Platforms / Frameworks

Microsoft Azure, Asp .NET Core API, Angular, MS SQL Server

Challenges

The client faced significant challenges in managing their supply chain efficiently as it included multifaceted logistics coordination and inventory optimization from corner to corner of multiple locations. They required ground-breaking solutions to streamline operations and improve real-time visibility into their supply chain processes. Their main challenges included:

- Fragmented data: Data silos across departments and locations led to ineffectiveness in data sharing and collaboration.

- Inventory management: Difficulty in real-time inventory visibility resulted in inventory unevenness and increased supply chain costs.

- Forecasting accuracy: Inaccurate demand forecasting led to stockouts or surplus inventory, impacting production planning and monetary performance.

- Logistics optimization: Suboptimal routing and scheduling of transportation increased lead times and logistics costs.

- Scalability: Legacy systems lacked scalability to handle growing production volumes and evolving market demands.

Solutions

Our team of experts indulged in comprehensive discussions with the client’s operations teams. We observed their processes in detail and understood their core requirements. Our developers decided to leverage Microsoft Azure Cloud solutions that provided our client with the following advantages:

- Unified data platform: Implemented a cloud-based data platform that centralizes data from disparate sources. This enables real-time visibility and collaboration throughout the supply chain.

- Predictive analytics: Leveraged advanced analytics and machine learning algorithms to improve demand forecasting accuracy. This reduces stockouts and excess inventory.

- Inventory optimization: Deployed inventory optimization algorithms to dynamically adjust inventory levels based on demand signals. This optimizes inventory turns and reduces carrying costs.

- Logistics management system: Implemented a cloud-based logistics management system for route optimization, vehicle tracking, and real-time monitoring of shipments. This led to lesser lead times and transportation costs.

- Scalable infrastructure: Leveraged cloud infrastructure to scale IT resources on-demand, supporting growing production needs. This ensures optimal system performance during surge times.

Business Impact

- Cost reduction: Optimized inventory levels and logistics operations led to substantial cost savings.

- Improved efficiency: Real-time data visibility and automated processes enhanced operational competence and decision-making.

- Enhanced customer service: Reduced lead times and improved product availability resulted in better customer satisfaction.

- Scalability: Cloud infrastructure provided the scalability needed to support business growth and adjust to market changes.

- Competitive advantage: Streamlined supply chain operations positioned the client for competitive advantage in the dynamic automobile industry.

Need more information?

Tell us what you are looking for and we will get back to you right away!