Modern warehouses strive for higher productivity. Hence, every advancement in accuracy and speed is an opportunity to excel. The pressure to deliver accurate and on-time orders has never been higher. However, manual picking processes fall short in accuracy and speed.

The cost of order picking is estimated to be as much as 55% of the total warehouse operating expense. – ResearchGate

Pick-to-light technology is the answer. It enhances warehouse productivity by guiding workers with LED light cues to each item. This helps businesses minimize errors and maximize efficiency. So, let’s dig deeper into this technology to understand its working and benefits.

Challenges faced by traditional picking system

High error rates

Manual picking processes often lead to picking errors. These errors include selecting the wrong item or incorrect quantities.

- Impact:

- Increased customer dissatisfaction due to incorrect orders.

- Higher costs associated with returns and re-shipping items.

Time-consuming processes

Manual picking typically involves workers searching for items based on paper lists or screens, leading to inefficient use of time.

- Impact:

- Delays in order fulfillment leads to decreased customer satisfaction.

- Inefficient use of labor resources affects overall productivity.

Labor-intensive operations

Traditional picking relies heavily on manual labor, requiring workers to move extensively throughout the warehouse.

- Impact:

- Elevated labor costs due to extensive manual involvement.

- Increased risk of worker fatigue and subsequent errors.

Scalability challenges

As order volumes increase, scaling manual operations can be difficult and costly.

- Impact:

- Difficulty in managing peak demand periods without significant investment.

- Potential loss of business opportunities during high-volume seasons.

Longer lead times

The combination of manual processes and high error rates often leads to longer lead times for order fulfillment.

- Impact:

- Adverse effects on customer satisfaction due to delayed order processing.

- Reduced competitiveness in a fast-paced market environment.

What is pick-to-light system?

Pick-to-light technology utilizes visual indicators, typically LED lights. It guides warehouse operators to locate and pick items from shelves or storage areas. Each item location has a light that illuminates when an order is ready to be picked.

Functionality: How it works?

- The pick-to-light system activates the corresponding lights when the order is generated. It is displayed at the specific locations of the items that need to be picked.

- Operators follow the illuminated lights to the correct pick locations, ensuring they select the right items in the correct quantities.

- Some systems may also include displays showing the number of items to pick or additional instructions.

Components:

- LED lights: These are installed at storage locations, illuminating to indicate which items to pick.

- Control system: A centralized software system that manages orders, coordinates light activation, and tracks inventory levels.

- Barcode scanners or RFID: It is used to verify picked items and update inventory in real time.

Benefits of pick-to-light system

- Increased picking speed: By providing visual cues for pickers, the system accelerates order fulfilment. It helps in reducing picking time.

- Improved accuracy: The LED indicators guide pickers precisely. This reduces human errors and improves order accuracy.

- Enhanced productivity: Handle higher volumes of orders in less time.

- Lower training costs: Reduce the learning curve for new employees.

- Better inventory control: Real-time updates and accuracy help maintain optimal stock levels and reduce discrepancies.

- Scalability: The system can be easily adapted to growing warehouse needs. It can support varying order volumes and product types.

- Reduced labor costs: Optimize workforce utilization and reduce labor expenses.

- Improved warehouse utilization: The system can lead to more efficient use of space and resources by streamlining workflows.

- Faster order fulfillment: Quick and precise picking allows for faster order processing. This leads to reduced lead times and enhanced customer satisfaction.

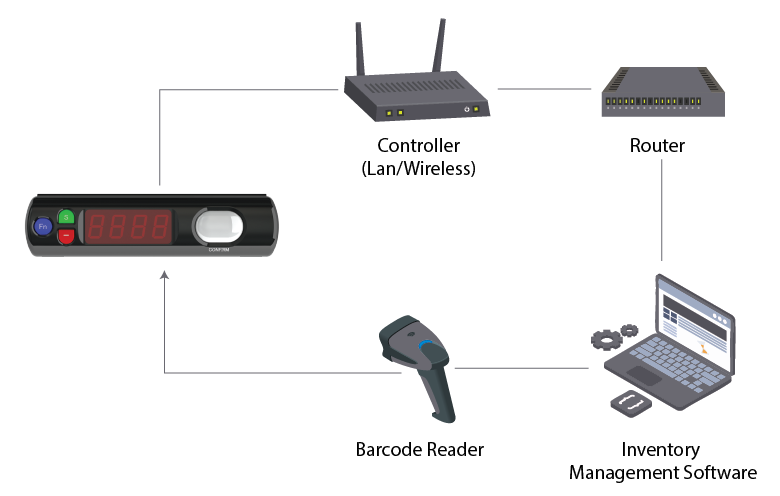

Architecture

When to use pick-to-light in a warehouse?

A Pick-to-Light system is ideal for warehouses that meet the following criteria:

- Orders requiring fast and accurate preparation.

- Small or lightweight items that can be manually moved.

- Facilities with a high volume of picking activity.

- Products with a medium to high turnover that demand rapid dispatch.

The LED picking system is a valuable tool in logistics, enhancing process speed, reducing errors, and enabling quicker deliveries. It is an excellent storage solution for specific goods types, and selecting the right storage system which is crucial to maintaining an efficient and effective supply chain.

Meeting the demands of modern logistics with LED picking system

Customers expect rapid, often customized deliveries, which creates intense pressure on logistics. Pick-to-light systems help companies meet these expectations by streamlining picking and improving speed without sacrificing accuracy. This technology is a valuable asset in high-demand settings, such as e-commerce and fulfillment centers during peak seasons.

- Consumer expectations: Faster, more personalized deliveries with minimal errors

- Pick-to-light system benefits for logistics:

- Ensures accurate, fast picking by guiding operators directly to items

- Adapts quickly to fluctuating demand, supporting seamless scalability

- Reduces reliance on extensive training, allowing temporary workers to work at a faster pace

- Enables real-time order picking

Suggested: What is the role of predictive analytics in supply chain management?

Supporting workforce optimization with smart warehouse solutions

While automation grows, human operators remain crucial in many warehouse tasks. Pick-to-light systems balance human roles and technology by reducing mental load, stress, and turnover among workers. New hires, seasonal, and temporary workers benefit from its intuitive setup, making it an ideal solution for high-demand periods.

- How it helps workers:

- Reduces the need for memorization and picklist rechecks

- Minimizes stress and repetitive tasks, improving job satisfaction

- Enables fast onboarding for new or seasonal workers

- Ideal for seasonal peaks:

- Temporary staff can perform effectively with minimal training

- Supports high demand without extensive reconfiguration or downtime

Suggested: How to prevent an 8% revenue loss through supply chain digitization?

Leverage pick-to-light system to make your warehouse smarter

Pick-to-light technology presents a transformative opportunity for efficient warehouse automation. Integrate advanced solutions such as AI, IoT, and data analytics to significantly enhance efficiency, accuracy, and adaptability.

Take the next step towards optimizing your operations. Reach out to us today for a comprehensive understanding of pick-to-light systems.