Supply chain operations have become more volatile. Worldwide disruptions, fluctuating consumer demands, and shortages of supply lead to inefficiencies that conventional systems cannot manage. Businesses that rely on outdated planning tools and siloed data are left scrambling to react, often at the cost of lost revenue, rising operational expenses, and declining customer satisfaction.

The old ways no longer work. Organizations now require more than visibility-they need intelligence that can predict and respond. Companies should adopt generative AI in supply chain to anticipate disruptions and optimize inventory.

This is where Needle comes in.

Looking to implement generative AI solutions for your business?

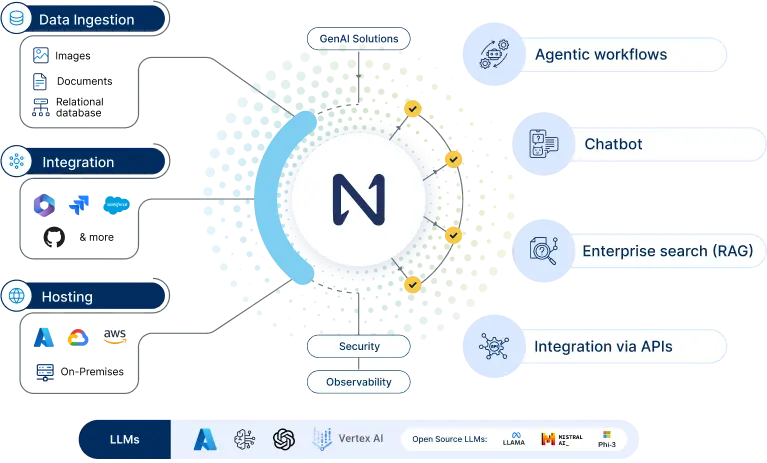

Needle, our customizable GenAI framework, simplifies complexities to help you make smarter, faster decisions. With Needle, businesses can design intelligent agents that adapt, reason, and drive efficiency across various functions.

As a generative AI framework, it enables supply chains to move from being reactive to predictive. Needle is powered by deep learning, NLP, RAG, agentic workflow, and advanced data synthesis. By analyzing real-time market trends, supplier risks, and logistics constraints, Needle automates decision making, optimizes resources, and enhances visibility across the entire supply network. The result? Faster, smarter, and robust supply chain operations, capable of adapting to any challenge before it becomes a crisis.

This blog explores key use cases of our GenAI framework in supply chain. It also showcases how GenAI can benefit supply chain operations.

Top 5 GenAI use cases in supply chain

1. Intelligent demand forecasting

Companies struggle with volatile demand, resulting in stockouts or overstock. Generative AI assists in demand forecasting by considering multiple sources of data to maintain the right inventory levels.

Let’s understand this with an example:

A global clothing retailer faces seasonal demand fluctuations and unpredictable fashion trends. With Needle, they monitor historical sales, fashion trends, and external market signals to forecast which goods will be in demand. This helps the company minimize inventory waste and stock shortages.

How Needle helps:

Needle integrates data from various sources that are mentioned above to build dynamic forecasting models. It helps in the following ways:

- Analyzes past and current trends to predict seasonal demand shifts.

- Integrates real-time market data to adapt forecasts dynamically.

- Simulates various demand scenarios to optimize inventory planning.

- Provides AI-driven recommendations to minimize overstock and prevent shortages.

Data sources Needle can use for this business case:

- ERP and sales history

- Market trends and economic data

- Social media sentiment

- Weather patterns and geopolitical events

Benefits:

- Reduced overstocking or understocking

- Improved demand forecasting accuracy

- Reduced operational costs

Patent data intelligence system powered by Needle framework

A legal tech company was facing issues with data visualization for patent analysis and document upload and patent comparison. They also required multi-lingual support. Explore how Needle helped the firm to address challenges related to large-scale patent data.

2. Automated supplier risk assessment

Supplier reliability is vital for smooth production. Generative AI analyzes several risk factors to anticipate supplier performance and avoid risks in advance.

Let’s understand this with an example:

A semiconductor company depends on several international suppliers for critical parts. With the help of AI-based supplier risk analysis, they identify early warnings of financial troubles in one supplier and proactively acquire substitute suppliers, avoiding production delays.

How Needle helps:

By analyzing supplier performance metrics and other data sources, Needle can:

- Monitor financial health and operational stability of suppliers.

- Detect early warning signals such as payment delays, legal disputes, or regulatory violations.

- Generate risk scores to help procurement teams identify vulnerable suppliers.

- Suggest alternative suppliers based on market conditions and past performance.

Data sources Needle can use for this business case:

- Supplier performance metrics

- Credit ratings and financial reports

- Regulatory compliance data

- News and geopolitical insights

Benefits:

- Minimized dependency on high-risk suppliers

- Enhanced supply chain resilience

- Financial and operational risk mitigation

3. Dynamic inventory optimization

It is challenging to balance inventory levels across warehouses. AI-powered optimization ensures that stock is efficiently distributed based on real-time demand.

Let’s understand this with an example:

A supermarket chain with multiple warehouses grapples with irregular inventory distribution, causing food waste in some areas while others experience shortages. Generative AI optimizes inventory distribution based on regional demand, reducing waste and enhancing on-shelf availability.

How Needle can help:

Needle leverages various data to optimize inventory distribution dynamically. It:

- Analyzes regional demand patterns to predict stock requirements across locations.

- Identifies inventory imbalances and redistributes stock proactively.

- Optimizes replenishment schedules to prevent overstocking and shortages.

- Accounts for logistics constraints like transportation costs and warehouse capacities.

Data sources Needle can use for this business case:

- Warehouse inventory data

- Demand forecasting models

- Logistics and transportation constraints

- Historical sales and regional trends

Benefits:

- Reduced holding costs and stock imbalances

- Increased product availability

- Enhanced supply chain efficiency

Suggested: key use cases of generative AI for the financial industry

4. AI-augmented logistics planning

Managing transportation routes efficiently can cut costs and delivery times. Generative AI dynamically optimizes logistics planning in real time.

Let’s understand this with an example:

A courier company must shorten delivery times during holiday shopping periods. With AI-driven route optimization, they modify delivery routes in real-time traffic conditions, cutting down transit delays and enhancing customer satisfaction.

How Needle can help:

Needle processes disparate data to optimize logistics planning in real time. It:

- Analyzes live traffic patterns to recommend the fastest delivery routes.

- Adapts routes dynamically based on weather disruptions and road closures.

- Optimizes fleet capacity and scheduling to maximize efficiency.

- Reduces fuel consumption by minimizing unnecessary detours.

Data sources Needle can use for this business case:

- GPS and traffic data

- Carrier capacity and availability

- Fuel price fluctuations

- Weather conditions

Benefits:

- Optimized delivery schedules dynamically

- Reduced fuel and transportation costs

- Enhanced last-mile delivery efficiency

5. Intelligent contract and compliance management

Manual contract reviews are time-consuming and prone to errors. AI-driven contract analysis streamlines compliance checks and risk detection.

Let’s understand this with an example:

A drug manufacturer needs to ensure that supplier contracts adhere to strict FDA regulations. With AI-powered contract analysis, they automatically identify non-compliant clauses and mark out potential legal risks prior to agreement finalization.

How Needle can help:

Needle utilizes data from various sources to automate contract compliance analysis. It:

- Monitors financial health and operational stability of suppliers.

- Detects early warning signals such as payment delays, legal disputes, or regulatory violations.

- Generates risk scores to help procurement teams identify vulnerable suppliers.

- Suggests alternative suppliers based on market conditions and past performance.

Data sources Needle can use for this business case:

- Contract management systems

- Procurement and financial records

- Regulatory and legal databases

- Supplier audit reports

Benefits:

- Reduced legal and compliance risks

- Faster contract approval and negotiations

- Improved regulatory adherence

Benefits of generative AI in supply chain

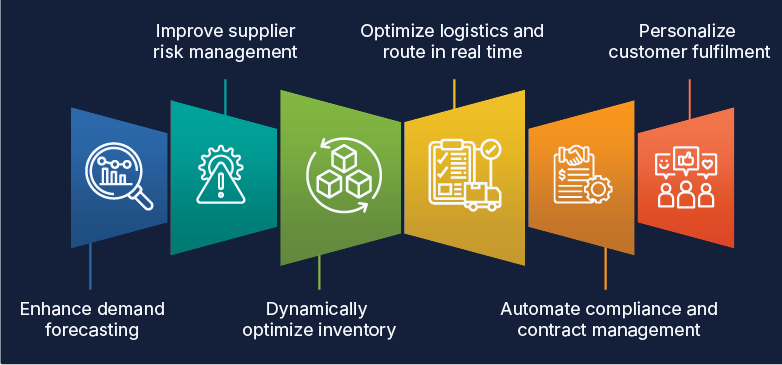

By leveraging GenAI use cases in supply chain, organizations can:

- Enhance demand forecasting: Generative AI optimizes demand forecasting by evaluating varied data sets, lowering stockouts and overstocking.

- Improve supplier risk management: AI-based risk analysis detects weaknesses in suppliers ahead of time, allowing for active risk management and supply chain strength.

- Dynamically optimize inventory: AI-driven inventory allocation minimizes waste, reduces holding costs, and provides product availability by location.

- Optimize logistics and route in real time: AI automatically optimizes routes of transportation considering traffic, weather, and fuel prices, lowering delays and costs of operation.

- Automate compliance and contract management: AI automates contract analysis, providing regulatory compliance and reducing legal exposure in supplier contracts.

- Personalize customer fulfilment: AI improves last-mile delivery and inventory planning, enabling quicker order fulfilment and enhanced customer satisfaction.

Why Needle – GenAI framework is a game changer for supply chain operations

Traditional supply chain management is based on dispersed data, manual interventions, and reactive decisions. Hence, it is susceptible to disruptions. Needle revolutionizes supply chains by bringing in real-time intelligence, automation, and predictive insights.

How Needle improves supply chain operations:

- Predictive decision making – Anticipates demand, supplier risks, and logistics bottlenecks by analyzing varied data sources.

- RAG-driven process automation – Automates procurement, inventory optimization, and contract management processes.

- Dynamic risk mitigation – Discovers potential disruptions ahead of time to enable proactive resolutions.

- Optimized resource allocation – Maximizes inventory distribution and transportation efficiency, minimizing waste and expenses.

- Seamless system integration – Integrates with existing ERP, IoT, and external data sources to provide contextual AI-powered insights.

Transform your supply chain operations with generative AI

The future of supply chain management is intelligent automation, real-time intelligence, and proactive decision making, all enabled by generative AI. Companies that adopt GenAI-powered solutions such as Needle can streamline operations, reduce risks, and stay ahead of market changes. Whether demand forecasting, supplier risk management, or logistics planning, Needle gives enterprises the agility to anticipate, adapt, and act.

With increasingly complicated supply chains, using outmoded techniques is no longer possible. Needle arms organizations with AI-driven intelligence to create resilient, efficient, and future-proof supply chains. It’s time to move away from reactive management to proactive optimization—led by generative AI. Talk to our experts to learn more or request for a demo.