Plant managers struggle to coordinate maintenance schedules, monitor equipment health, and optimize production flows. AI agents predict maintenance needs, maintain product quality, and automatically adjust operations for peak efficiency. These agents also detect production inefficiencies by analyzing machine telemetry data and workflow patterns.

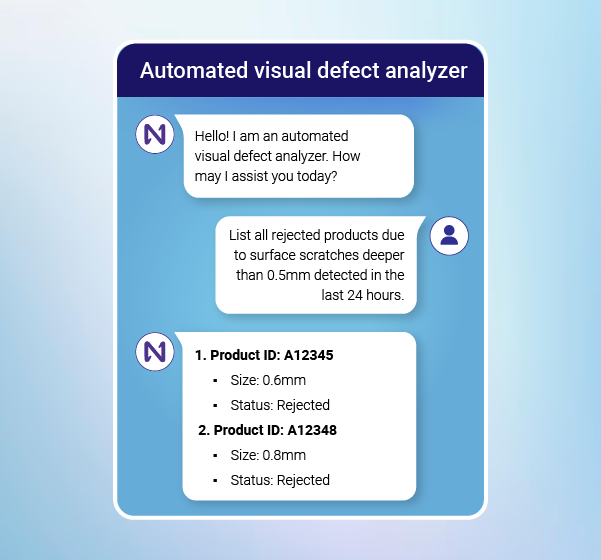

Manufacturers struggle with consistent and accurate detection of visual defects across high-speed production lines. Needle’s AI agents can process real-time camera feeds to identify, classify, and track product defects before they reach customers.

Real-time image analysis and Classification

Monitor production line #3 for surface scratches deeper than 0.5mm on aluminum panels and automatically reject affected parts.

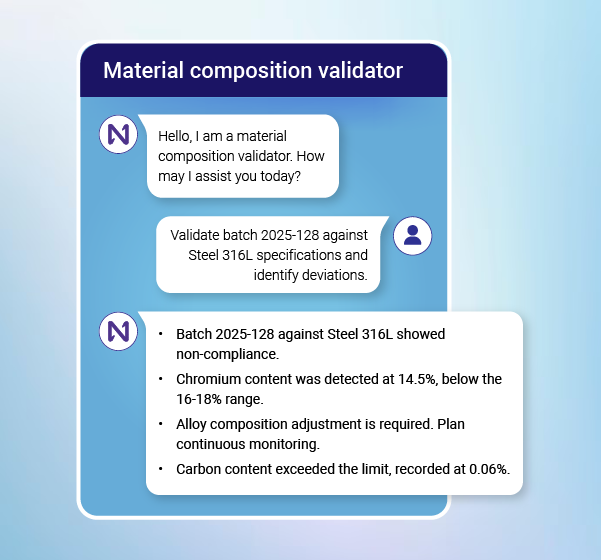

Ensuring correct material composition is critical in manufacturing. Needle can help you to verify the correct material composition through AI agents. These agents can analyze your spectrometer data to verify material compliance and spot any flaws in real-time.

Spectral analysis and Validation

Validate steel composition for batch #2025-123 against grade 316L specifications and flag any deviations.

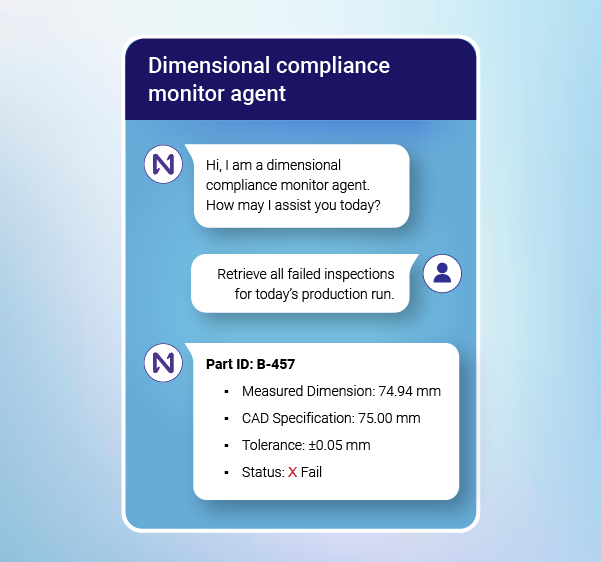

Production teams face frequent challenges in maintaining dimensional accuracy for complex parts. AI agents can integrate with your 3D scanning systems to perform real-time verification against CAD specifications, ensuring precise dimensions across the production line.

3D measurement and Verification

Check critical dimensions on automotive component A-123 against CAD specifications with ±0.02mm tolerance.

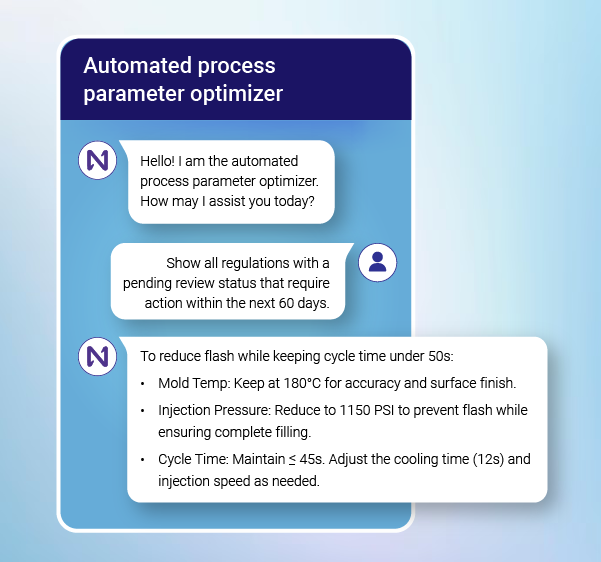

Manufacturing processes require precise control of multiple parameters. Needle’s process control AI agents can analyze and adjust your multiple variables to maintain optimal product quality. That’s how, AI agents can help you to maintain exact parameter management.

Multi-variable process control

Optimize injection molding parameters for part #XYZ-789 to minimize flash while maintaining cycle time.

Choose us and experience the difference. We leverage the power of GenAI-powered solutions to enable you to craft personalized journeys that resonate with every customer. This drives engagement and ignites brand loyalty. Get expert guidance, seamless integration, and a strategic approach to transform your business processes.

Leverage AI agents to optimize production, prevent downtime, and ensure operational productivity.

by submitting this form you agree with the terms and privacy policy of Softweb Solutions Inc