Several industries are undergoing digital transformation to streamline processes. However, the manufacturing sector has been relatively slow. But the time has arrived when applying data analytics in manufacturing can ensure improved decision-making and enhance performance.

Coupled with the rapid development of artificial intelligence, advanced analytics, robotics, emerging IoT-powered sensors and devices, Industry 4.0 offers manufacturers the ability to gather, store, process as well as utilize data in daily operations. Furthermore, business intelligence and business analytics help to draw insights about potential improvements.

Besides, the manufacturing industry frequently requires new solutions to automate large-scale processes and speed up execution time. Through this blog post, we aim to highlight how data analytics can transform the manufacturing industry. Data analytics in the manufacturing industry enables companies to optimize production, reduce downtime, and enhance overall efficiency.

How Industry 4.0 is a game changer for factory owners

Webinar agenda

- How Industry 4.0 is a game changer

- The role of IoT and data analytics in the manufacturing industry

- IT/OT Convergence: Why it’s important for IoT adoption

- Current market trends and value

- Q&A session

Get ready with the Industry 4.0 revolution

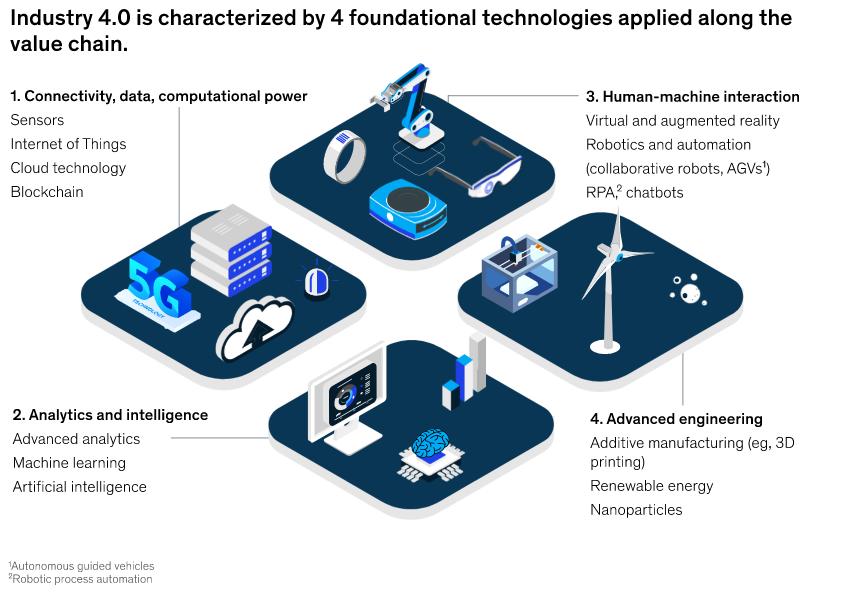

The concept of Industry 4.0, is not that simple; it bundles many technologies for several contexts. However, manufacturers that utilize Industry 4.0 digital solutions are better-positioned to move faster as compared to traditional companies. Everything from production efficiency to product customization can be transformed with the power of connectivity, advanced analytics, automation and more. The combination of these technologies helps manufacturers to improve speed to market, increase service effectiveness as well as create a new business model for better productivity.

Whether an organization is focusing on the resilience of their supply chain, restore operations, or desire to overcome production challenges, Industry 4.0 is the way to go about it.

Here’s a diagram that demonstrates the foundational technologies of Industry 4.0 for a better understanding:

Source: www.mckinsey.com

Let’s understand some data challenges in manufacturing:

- The increasingly distributed data which is often collected from different sources and presented in inconsistent ways is challenging for manufacturers. Although many organizations can capture data correctly but fail to further analyze and utilize it efficiently.

- Another data challenge refers to the integration of new technologies into a company’s legacy systems such as ERPs, machine-level control systems, execution systems and even production planning systems.

- Not to forget, the rapid industrial data that manufacturers generate and collect leads to overhaul the storage management systems and further fails to keep pace with timeliness.

- The more the volume and complexity of data grow, the more the visualization and interaction tools become complex. Although manufacturers are not in charge of solving this particular data challenge, they should be aware of its influence.

- The use of several connected tools and industrial control systems can overload the gateways that connect various IoT devices. Moreover, with limited computing power, manufacturers can be at the risk of unauthorized access, leaks and security issues.

Now that we have discussed the few data challenges, let’s understand how data analytics in manufacturing industry can help in addressing these issues.

How is the manufacturing sector innovating with data analytics

Analytics offers actionable insights that explicitly support the most critical business choices of a company such as finding:

- Which product yields lower margins?

- Which providers are most likely to disrupt our manufacturing?

- What is the business competitiveness on sales incentives?

The initial wave of analytics aims at improving product growth because products are usually at the center of the manufacturing process. Other common areas of emphasis include supply chain optimization, sales and marketing budget control, warranty spending reduction and overall financial management improvements.

In these specific fields, data analytics can bring breakthrough insights with a significant effect on business results and potentially provide an incredible ROI on the analytics investment of an organization. Additionally, the use of analytics for manufacturing industry can promote new revenue models built around selling services of a manufacturing company.

Data360 Program = Customized Consulting + Services

Here are a few benefits of data analytics establishing the importance of data analytics in manufacturing industry

1. Maintaining lower operating costs

What if employees were able to perform an immediate supply chain analysis? What if a collaborative, enterprise-wide sales dashboard could help to monitor revenue stream? With search-driven data analytics for manufacturing, employees gain the ability to handle ad hoc queries in seconds. They get results in the form of a visualization model with easy-to-read data and are embedded in shared workflows and portals.

This will help to decide how a manufacturing unit spends funds as well as consider eliminating costly reports or pay-per-user license fees for data solutions.

2. Automation balancing and human labor

Many manufacturers often face challenges maintaining warehouses and automating certain procedures. But at the same time, in specific roles, humans are irreplaceable and often vital as supervisors. By leveraging workforce analytics, manufacturers can introduce workable staffing solutions and monitor ROI over time, especially as manufacturers adopt automation in different segments of their operation.

3. Cyber threats and violation of data

A variety of the best practices are involved when it concerns cyberattacks such as preventing phishing scams, training employees, updating antivirus and more. For manufacturers, these are crucial considerations especially when massive data is being collected frequently. Therefore, implementing an enterprise-grade data security solution helps to keep data safer from any misuse. Here are a few advantages to reap:

- Specific authorization permissions

- Security layer over every data object, level and rows

- Unified data governance and management

- Auditable and traceable data insights

4. Effective decision-making

Using advanced analytics in manufacturing does not only help to make effective decision-making but also helps to resolve operational issues. Data analytics allows manufacturers to examine billions of data rows from different sources and enables them with the ability to identify inefficiencies, opportunities for organizational enhancement and share insights with authorized users.

Manufacturers: Data is the way

Data-driven manufacturing is becoming a strategic necessity that unifies both internal and external data. As the data expands exponentially, manufacturing firms should apply data analytics to get significant value with better speed and efficiency. If you’re set to make a significant impact with data, get in touch with our experts and start your data journey.