Let’s suppose that a caterpillar goes into a cocoon and comes out just as a faster caterpillar. It’s interesting, but not impressive because that’s just a change. But the fact is that a caterpillar goes into a cocoon and emerges as a butterfly. That’s the transformation, a real transformation. Isn’t that what we all want?

From the time we have been living and working, we have been grappling with change. But something feels different this time around. It’s the speed at which the change happens. Think about it: the way we work, we communicate, we play, we shop, or we bank, all has changed just in the span of the last two decades. Thanks to digital innovations! With big data, IoT, AI, and cognitive technologies, companies are rebelling against old ways of doing business to get customer insights, predict demands, streamline operations or orchestrate supply chains. IoT-powered digital twins are at the forefront nowadays.

How is the banking industry coping with the digital transformation wave?

What sort of advantages can the banking industry look towards with digital transformation? It’s our pleasure to have a conversation with Alex Jimenez on the impact of digital transformation of the banking industry.

IDC forecasts that by 2020, 60% of global companies will leverage digital twins to monitor product or asset performance, improve the quality of goods, and deliver exceptional customer experiences. By 2021, Gartner predicts that half of the large industrial companies will use digital twin and gain a 10% improvement in effectiveness. And MarketsandMarkets estimates that by 2023, digital twin market will reach to USD 15.66 billion. As digital twin’s increasing popularity is evident, let’s see what it is and how it can be a powerful technology to accelerate your digital transformation.

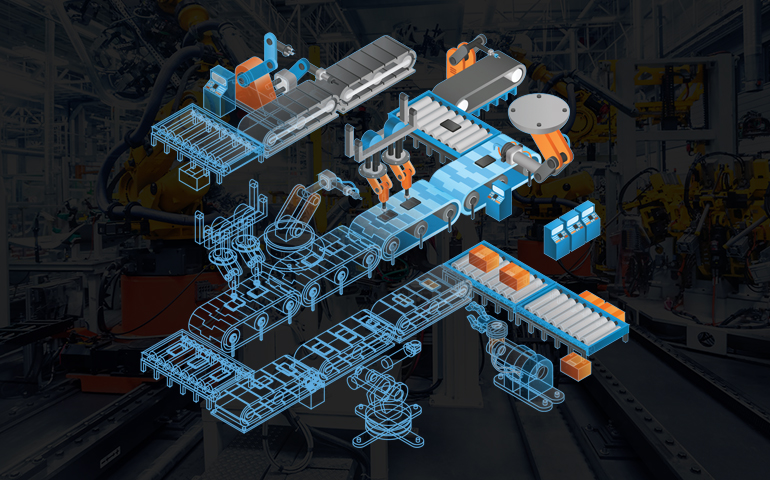

Digital twin: an integral part of your IoT-fueled business

Webinar agenda

- Why digital twin matters and what it is

- Its architecture and how to create it

- Core components

- Digital twin implementation

- Implications in different industries

What is a digital twin?

Digital twin is a virtual representation of a real-world machine, device, process, or system, helping users to visualize what is happening, take away vital insights, and share impacts with others, empowering collaboration.

For example, when you are having coffee, you can get an alert from your air-conditioner, industrial valve, the machine out in the field, or even a warehouse, “Hey, you need to carry out maintenance on X part in the next two weeks.” And this feature of a digital twin has gained immense popularity amongst factory owners and machine rental service providers, because they pay around $20B to maintain their industrial machines as they are critical to operations. Overall, digital twin gives an X-ray vision.

Apart from giving signals for maintenance in advance, let’s see how digital twin can prove as a powerful business strategy.

It can create new customers and enterprise value

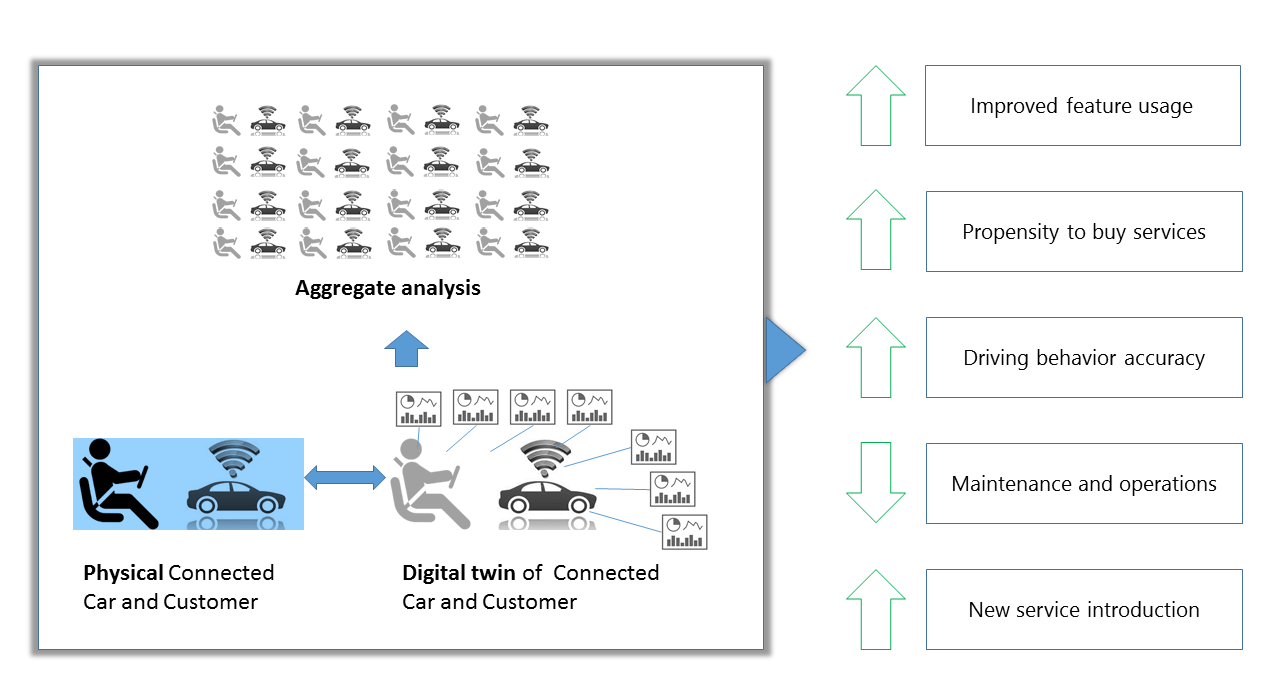

The applications of digital twin on turbines, jet engines, and locomotives are well-known for predictive analytics, anomaly detection, and performance optimization in the industrial domain. But let me show you here what happens if we apply digital twin on something which we use daily. If digital twin applies to the connected car, it can answer many user-centric questions valuable for any enterprise. Like:

- What are the features most commonly used by customers? How regularly are they used? Does a feature usage change over time?

- How often do customers listen to service recommendations? Are the recommendations relevant, timely, and impactful?

- Can historical analysis of features encourage a company to come up with an individual customized service plan?

- How frequently are the driving assistance features used in the vehicle, for instance, lane departure warning system, blind spot detection, driver drowsiness detection?

Such questions ultimately can help companies to improve the business, product quality, customer experience, and operations. When the duplicate image of a connected car is combined with a virtual customer, the benefits will be manifold. The highlight of the benefits of creating digital twins for a connected car is captured in the following image.

It advances product quality and innovation

Almost every physical product out in the field now relays data. With digital twin, this data can be used to gain invaluable insights of the product or may be an industrial machine as well, like how its’ being used, what it is made up of, how it performs in different conditions, maintainability records, and more – to advance product or a machine design and quality as well. Armed with this analysis, product designers can validate a better version of the prototype which will be more valuable for customers in the right areas.

Moreover, with more reliable data at hand, designers will be able to run more rigorous A/B testing, what-if analysis, and simulations. Here, the decisions will be more data-driven and drawn from the real-world than the traditional approach of theoretical modeling.

You would be surprised, but digital twins are being used in product design from almost a decade now, particularly for highly capital-intensive products such as jet engines, steam turbines, and other heavy machinery. To know how digital twin gets utilized for capital-intensive products, watch the following video:

It facilitates predictive maintenance

As the approaches to production have evolved, methodologies for maintenance have also changed and continue to develop, thanks to improvements in technology, mainly digital technologies, shifting attitudes, and in some cases, regulatory requirements. Consequently, more facilities, I would rather say factories, are moving from a reactive model to a preventive or predictive one.

Since digital twin is responsive – receives data from sensors embedded in the physical asset and alters as the asset changes – it delivers a thorough real-time model of the asset and its performance under various working conditions. It lets technicians in a factory to look for abnormal patterns and spot problems that may not be easily recognized through visual inspection or other usual methods. Further, as a virtual replica, a digital twin is not bound by time constraints – meaning one can run exhaustive simulations to calculate how and when the asset will degrade based on a variety of factors like its’ runtime, age, exposure to harsh environments, and many more. Using the results of these simulations, technicians can predict how and when the asset is likely to fail, long before it happens.

This will result in factory production lines facing minimum unplanned downtime, less maintenance costs, improve equipment performance and reliability, extend assets’ lifespan, and advance safety.

Apart from creating new customers and enterprise value, advancing product quality and innovation, and facilitating predictive maintenance – companies can realize many other benefits by adapting digital twin. To know more in detail, stay tuned to us as we are coming up with a webinar on digital twin on November 01.

In the last, I would like to put a quote from management thinker Peter Drucker. He says, “The greatest danger in times of turbulence is not turbulence itself, it is to act with yesterday’s logic.”

Isn’t it like, “The greatest challenge in times of digital is not digital itself, it is to keep doing the things as we have always done them.”