What are manufacturers worried about the most when it comes to handling equipment?

- Frequency of maintenance tasks

- Monitoring of equipment

- Unplanned breakdowns

- Costly repairs

- Maintenance costs

Businesses that depend on complex machinery know that regular maintenance is essential to keep them functioning and running efficiently. A common practice that manufacturers have adopted is preventative maintenance, which entails regularly inspecting equipment.

Traditional maintenance vs. predictive maintenance

Traditional maintenance checks are manual, time-consuming, and can be an inefficient use of manpower. If a maintenance manager is responsible for only a handful of components or equipment, planned maintenance is a viable option. While preventative maintenance is a good practice to follow, it can still lead to unnecessary costs and downtime.

An emerging practice of predictive maintenance, however, aims to make maintenance more efficient and cost-effective. Predictive maintenance is the practice of forecasting machine failure and preventing it from happening. It empowers organizations to auto-generate a work order when equipment readings fall outside of predefined boundaries.

To understand predictive maintenance in-depth, read our whitepaper.

AI and predictive maintenance

Predictive maintenance has emerged as a primary advanced analytics technique for the manufacturing industry. It helps IoT-enabled companies with increased operational efficiency and productivity.

It is expected that, by 2022, the global predictive maintenance market will reach around 11 billion U.S. dollars. – Statista

Predictive maintenance when empowered with AI techniques goes beyond historic analytics. Essentially, it helps organizations predict future scenarios, allows them to assess a number of possible outcomes, and decide an appropriate course of action.

AI-driven predictive analytics use a combination of techniques and tools such as business rules, algorithms, machine learning, and computational modeling procedures. These techniques are applied to a variety of data sets including historical and transactional data, real-time data feeds, and sensor data. It helps companies to gain a full picture of equipment efficiency and health by syncing measurements and autonomously monitoring that data. This allows a maintenance team to respond to fault notifications, and create, access or process work orders related to the notification in real-time.

How it works

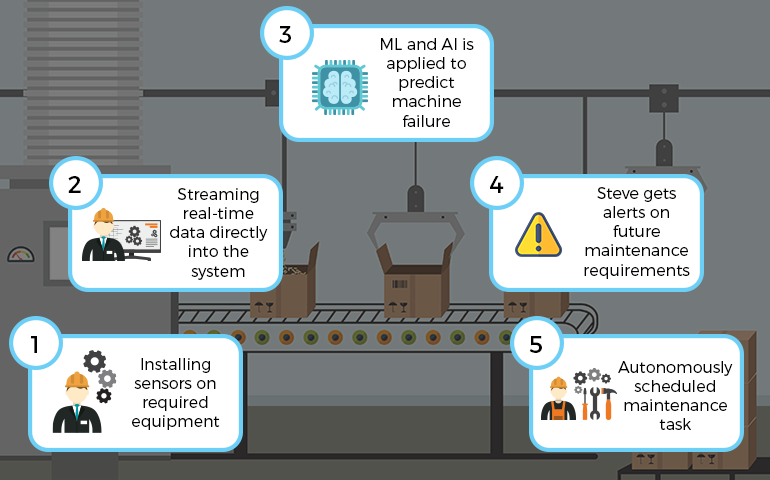

The key component of predictive maintenance is the data collected via IoT sensors connected to machines. Sensors detect a variety of data and feed the same to a system that further converts the raw data into a formatted and manageable form. The data provided from sensors can give you a great deal of information on how your machines are running.

AI algorithms are then run on the collected data to get the context of machine performance. Based on the processed information, the system then alerts you when maintenance is needed or if a breakdown is imminent.

Let’s see an example of how Steve, a factory floor manager, uses AI-driven predictive maintenance:

Business benefits of implementing AI for predictive maintenance

One of the major benefits companies can get from adopting predictive maintenance that leverages artificial intelligence is getting alerts when a fault is about to develop. A predictive maintenance implementation based on machine learning models help companies to identify patterns from historical datasets to keep track of successfully running components and about to fail components.

AI-powered predictive maintenance has several benefits for manufacturers:

- Get a great return on investment

- Foresee when a machine needs care

- Save on repetitive costs

- Reduce maintenance costs

- Reduce major equipment failures

- Extend equipment life

- Reduce unscheduled downtime

- Improve response time

- Generate an auditable trail of machine performance and behavior

- Reduce production losses

How to implement a predictive maintenance strategy

Making predictive maintenance work for you depends on how wide-scale you want to implement the process.

Here are some steps to follow:

Design and plan the program

Identify which machines to IoTize for the program by taking a close look at the equipment failure history. Machines that fail often have the most potential for cost reductions and reliability improvements. It is essential that you deploy IoT on machines and equipment that serve a critical role in operations and would be highly disruptive to the business if they failed.

Select appropriate tools technologies

Choose which of the above technologies would be most effective to monitor the condition of your equipment. What sensors do you require? Do you want to measure temperature, pressure, water quality or other parameters? Select the tools and technologies that will provide such information.

Allocate proper resources

Schedule tasks such as data collection, analysis, reporting and tracking, and allocate funding for predictive maintenance technology investments or, for a predictive maintenance provider to assist.

Convert data into action

Leverage the appropriate tools to turn condition monitoring data into action. Choose a service provider that offers monitoring services along with AI techniques that help you generate corrective work orders.

Utilize interactive reports & dashboards

With reporting and dashboard tools, organizations can consistently document work order history, failures, costs, and trends. This helps to track machine performance and avoid unnecessary downtime.

Note: Don’t implement predictive maintenance on equipment that is not as crucial to operations. It’s important to use it on equipment where IoT sensors can easily detect anomalies. Not all machineries and equipment are good candidates for IoT sensors.

To implement AI-powered predictive maintenance, it is essential to have someone who is qualified to understand the technical aspects of the system. This role requires a mix of expertise in IT and knowledge of the machines to be monitored. Depending on the scale of your operation, it makes deploying these technologies easier when you hire the right data experts.