The new emerging technologies are impacting the manufacturing industry in a big way. Since IIoT solutions and real-time data processing are increasing, the predictive analytics is empowering the processing of a huge amount of data captured from all the interconnected machines.

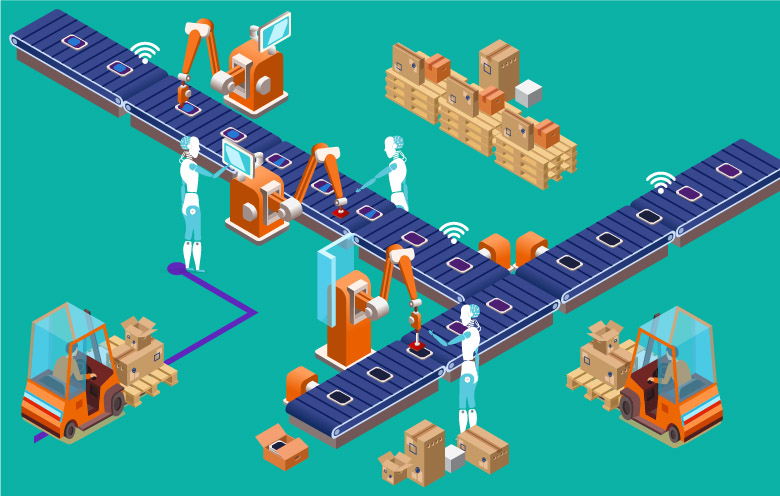

In the present situation, the logical decision-making process involves human participation along with the processors of low-level machines. Artificial intelligence will enable machines to detect fluctuations by themselves in the manufacturing process. They will have AI-enabled smart manufacturing capabilities to respond in real-time and will require less human interference.

Implementation of AI technology will enable:

- Mass customization

- Comprehensive automation

- Implementation of intuitive robots

- Receptive intelligent machines

The manufacturing industry touches almost every side of our daily lives. Companies are continuously pursuing means to enhance the processes and reduce costs. Besides, there have been several factors which are driving elements in the course of the industry. There have been several factors driving the change in the industry, while it was quality for three decades, it has been safety for two, and now the environmental sustainability is a growing factor for such transformations.

AI strategy and planning workshop

Artificial intelligence is transformational, and adopting this technology will enable companies to reshape their strategic vision so that they no longer rely on what they think is true, rather, leverage factual-based decision-making capabilities.

External concerns have forced the industry to bring about such a change in the process of manufacturing that it not only supports the outside environment but also improves the internal process and minimizes challenges for manufacturers.

The prime force for using numerous features of AI and ML in the manufacturing process is the increase in demand for tailored products at reasonable rates.

The use of machine learning is higher (79%) in the manufacturing and high tech sector specifically as is the institutionalization of enterprise knowledge using AI (66%) and cognitive AI-led processes/tasks (60%). Most companies want to automate manufacturing to increase productivity (66%), minimize manual errors (61%), reduce costs (59%) and refocus people’s efforts on non-repetitive tasks that benefit from human intervention (50%). –Infosys

Let’s take a look at how these technologies are transforming the manufacturing industry:

1. Predictive maintenance minimizes operation and maintenance (O&M) expenses

Cognitive AI technology, smart sensors, and an interconnected network of machines will help plant engineers to monitor devices on the floor. As a result of continuous monitoring, floor managers will be able to generate predictive analytics.

The speedy rise of AI and associated technologies are bringing digital twin technology to the manufacturing sector. AI has the capability to analyze the data that sensors collect from multiple sources. This data is further utilized to detect anomalies and identify situations that can lead to failure. Various companies are using several AI technologies to lessen equipment downtime.

By 2021, half of the large industrial companies will use digital twins, resulting in those organizations gaining a 10% improvement in effectiveness. – Gartner.

2. Improved supply chain management

A number of companies have started using AI and ML based smart factory solutions to improve global supply chain management since modern supply chains produce a huge amount of data. With the help of AI, these companies can analyze the data properly. Also, they can form it into valuable fragments of information. Hence, it becomes easy to adjust to varying market situations.

Some tech companies have even developed software as a service (SaaS), a customized AI-based supply chain management solution.

We can take the example of IBM’s Watson Supply Chain system that uses cognitive AI technology to monitor the process of supply chain. This system accumulates and evaluates data from diverse sources such as social media portals, news feeds, etc.

Ultimately, using AI and ML tools we can create a unified and consistent ecosystem which enables the continuous interchange of information. The system will not only sustain itself, but also improve the process in every facet of supply chain management.

3. Seamless quality control

The manufacturing sector is experiencing AI and ML-based quality assurance as a new research frontline. Most manufacturing companies have started using the network built upon computers and sensors to eliminate low-quality products. However, the AI and ML-based system delivers a continuous quality control over the entire manufacturing process.

Instead of depending on manual examining processes, manufacturers now use sensors and big data to find out faults with accurateness. This allows establishments to enhance the quality of low-quality items and avoid dumping them. It decreases the delay in exclusive production which remains to mound up in previous quality control methods. Hence, it may result in a decrease in the demand of human workers in quality control in coming times.

4. Improved human-robot collaboration

The upswing in AI and ML-based smart factory solutions is giving a new shape to the industry, which is uniting humans and robots to work together in the future.

With the advancement of new technologies, humans will work along with robots to create supple manufacturing processes. It is expected that working with next-generation smart robots will be safer and adaptable for human employees.

There are possibilities that we will have smart robots in the near future that will work directly with humans. The robots may have virtually infinite applications which may improve efficiency and flexibility in factories and may be able to identify patterns and learn to amend their responses consequently.

5. Buyer-centric manufacturing

Considering the protection and promotion of the interests of consumers, today manufacturers are determined to focus on buyer-centric manufacturing as the demand for customized products is rising. In this context, AI and ML-based technologies are enabling companies to build smart industrial processes to adjust to the variable demands of consumers.

This definitely needs a wide-range network that can connect consumers directly to the manufacturers. By connecting IoT with IIoT, this is fairly possible. The companies will be able to collect data from consumers and work upon the consumers’ demands. This will enhance the level of the manufacturing industry and enable them to match the consumer expectations.

AI and ML are the strengths of Industry 4.0. These technologies constantly improve the quality of production and collect data from products and equipment in the field. This data serves as vital information that forms the foundation for product development and essential commercial decisions.

When the production is based on the order, it will not only reduce manufacturing waste, but also allow vigorous supply chains. Since the production lines will be rapidly associated with cost-efficient and new products, consumers and manufacturers both will have a win-win situation.