It’s been a year since the development edition of HoloLens started being shipped out. Today, there are over 150 mixed reality applications available in the Windows Store and the device is available in 10 countries across the globe. Windows Mixed Reality, Microsoft’s mixed reality platform, is already built into Windows 10 making development accessible to everyone.

While HoloLens is described by Microsoft as a mixed reality device, it is for all practical purposes, an extremely advanced version of augmented reality (AR). For companies interested in building an AR/VR application, HoloLens is not the only game in town when it comes to augmented reality. There are many other devices today that have similar features, with some even having capabilities that are not present in HoloLens.

Meta, Vuzix, Recon and Daqri are some of the alternative AR headsets, with Google-backed Magic Leap and Apple’s rumored AR headset expected to be launched this year.

All of these devices can add value to an organization in the form of AR-based enterprise solutions. In this blog post, we will explore how an augmented reality field service application can help companies set up a more efficient maintenance program.

Challenges faced by field service engineers currently

- Inability to meet customer demands consistently due to high expectations

- Lack of real-time communication and inability in allocating the right resources to the right situation

- Difficulty in locating the right equipment in order to carry out maintenance

- Dealing with the rising cost of operations

- Ensuring that the field service technicians meet all the safety and liability standards

- Increasing service delivery optimization through better employee performance and adhering to internal service level objectives.

Mobile AR could become the primary driver of a $108 billion VR/AR market by 2021, with AR taking the lion’s share of $83 billion and VR $25 billion. – Digi-Capital

How mixed reality can help enterprises overcome these challenges

1. Better field service through remote instruction and real-time communication

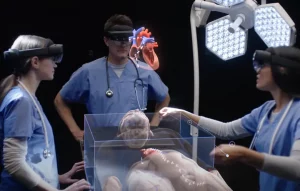

As any public facing enterprise knows, in today’s age of social media channels, all it takes is one irate customer to damage your reputation. When you equip your engineers with HoloLens or any other AR headset, no matter which technician is sent out for the repairs, he can have access to the entire knowledge base of the company and can also call the subject matter experts through a video call.

He can receive step-by-step instructions through remote experts along with visual diagrams. The integrated video conferencing results in real-time collaboration. This is a big help in improving the quality of service offered since the company no longer needs to be dependent upon technicians with specialized skills. It results in more efficient deployment of field crews since the need for a physical presence is reduced and guidance can be given from any location.

2. Instant access to past maintenance records

If the field service technician needs to access the previous work done on the equipment, all he has to do is quickly pull up the records on his headset. He does not have to call up someone or go through the records on a laptop or even a mobile application as technicians were doing previously. This means that he can work hands-free and can speed up the maintenance work.

Just like a mobile or desktop application, an AR app can draw data from enterprise applications. This includes data sources such as training manuals, maintenance procedures, asset inventories, historical performance data vis-à-vis real-time data and service records.

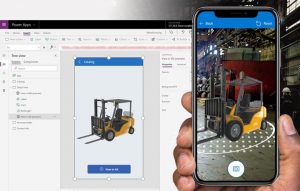

3. Ability to view product catalog for the relevant parts while working on the job

A field technician can quickly view all the relevant spare parts in 3D augmented view needed to carry out the repairs without having to refer to his product catalog mobile application or any paper printouts. All the products can be in his line of sight via his headset.

4. Track the location of a particular piece of equipment

Field technicians can easily navigate to reach the exact location of the equipment that needs to be replaced. Some of the AR headsets in the market today have GPS receivers along with a range of sensors that make this possible. These types of AR headsets can help the technician locate the faulty equipment and superimpose a virtual model on top of their field of view which makes repairs quick and easy.

5. Training of remotely located equipment and running simulations

New employees can be trained on equipment that is located on remote sites or in situations where a mistake can result in injuries, death or damage to property. Field technicians can also be given on-the-job training.

6. Improved safety for lone field workers and the resulting reduced liability

Companies have to send two field workers even if the job on hand requires just one because of state regulations or company policies relating to employee safety. But with the adoption of smart glasses, a lone field worker can receive instructions while keeping both hands free. This is especially important in jobs such as working on power lines, wind turbines and similar situations.

If you want to know more on how AR/MR can help you develop a more efficient field service maintenance program, get in touch with our mixed reality experts for a demo.