OEE stands for Overall Equipment Effectiveness. It measures how well a company runs its operations. In manufacturing, it refers to the percentage of output produced compared to the input (raw materials) used to produce it. A higher OEE means that the company is running at a high-efficiency level, while a lower OEE indicates that the business is not operating effectively.

It is considered the gold standard of productivity by manufacturing companies. The ability of your equipment to perform at its maximum level and yield high-quality products is the key to your success. OEE detects the percentage of productive time in the total duration spent in the manufacturing process.

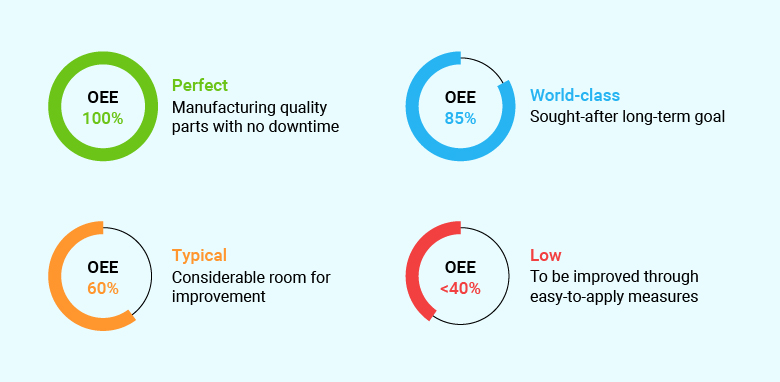

Say for example, a company is manufacturing only good products in the least possible time, without any downtime, then their OEE score would be 100%. And any value less than 100% reflects an opportunity for improvement.

Three factors are taken into consideration while deriving OEE:

- Availability rate – The percentage of time a machine is producing without any downtime

- Performance rate – The ratio of output yield compared to standard output

- Quality rate – The ratio of good production compared to the actual output

The calculation of OEE (%) = Availability rate × Performance rate × Quality rate

Implementing an OEE dashboard with Power BI helps manufacturing companies detect losses, discover and abolish sources of waste in the process and measure their success. We live in an era where market competition increases continuously. In such a scenario, a slight surge in OEE percentage leads to huge profits and a decline leads to losses.

Though back in the 1980’s when Seiichi Nakajima introduced the concept of OEE, the machines were not that well-constructed and there used to be high chances of them failing. But in the past four decades, the construction of machines has improved significantly and now they are far more dependable and less likely to fail.

Considering OEE is highly useful for manufacturing operations as it helps you to detect losses, enhance growth, and provide numerous ways to improve equipment productivity. OEE solutions gather data from disparate sources and analyze it using tools like Power BI and Tableau to provide useful insights for the betterment of your business growth.

Data360 Program = Customized Consulting + Services

Benefits of OEE analytics to boost the performance of your manufacturing operations

1. Steady production volume

As a manufacturing company, the success of your business depends upon how efficiently you handle production. You are expected to respond to your client’s demands with a high-quality product in a short time, whether your business model is B2B or B2C. At the same time, maintaining consistency in production quality, quantity and turnaround time eventually helps you to achieve your business goals.

With the implementation of OEE technology, you get visibility into your manufacturing process and performance that enables you to meet your production targets. Moreover, OEE analytics helps you to control your operations from top to bottom, allowing you to visualize and analyze your progress in detail. OEE also assists you with proper resource allocation to ensure maximum production volume.

2. More efficient manufacturing processes

Manufacturing facilities handle several processes simultaneously. Hence, a shop floor gets extremely busy and monitoring every process manually becomes tedious. However, it is essential to monitor all the stages of your production processes carefully to maintain the smooth functioning and quality of products.

Here is where OEE comes in. An OEE platform provides you with the live status of all your processes. You can monitor the functional status of all your equipment and processes for constant improvement. Using the right software that integrates with your system, you can find and spot glitches easily and your workforce can correct the primary issues simultaneously.

The OEE systems have embedded performance and analytics modules. The performance module tracks the outcome of processes and delivers instant updates. On the other hand, the analytics module analyzes the numbers and derives insights to help you to improve your net profit. Also, there is a Microsoft Power BI viewer in analytics to track your KPIs and discover the areas for improvement with machine learning.

3. Performance visualization

OEE in manufacturing measures how efficiently a company uses its assets to produce goods or services. Companies use their production data and financial statements to determine what they spend on raw materials, labor, utilities, etc., for calculating OEE. It also helps to compare those costs to the revenue generated from selling products. Companies can then calculate their operating expenses per unit produced.

4. Competitiveness

Companies can use OEE to help their workforce understand how well they are performing compared to competitors. Using this information, companies can find ways to reduce costs and increase revenues, thereby gaining a competitive advantage.

5. Reduces machinery cost

Manufacturing companies often have to purchase expensive equipment and machinery. However, if a company’s OEE is low, it may mean that the company is not able to use its equipment and machinery efficiently. Therefore, companies should strive to maximize their OEE to save money and increase profits.

6. Enhances return on investment (ROI)

The integration of an OEE system improves the efficiency of your equipment which in turn enhances its productivity. Moreover, the return on investment is higher if your manufacturing unit produces 25% more products over the same period with OEE analytics.

7. Predictive insights

The OEE system collects data to provide insights on the equipment downtime patterns and sends you alerts when your machines require maintenance. OEE system reduces unplanned downtime, minimizes costs and increases dependability.

Smart manufacturing with Softweb!

No matter what manufacturing segment your business falls into, Softweb Solutions has an OEE system suitable for all your business requirements. With years of experience in providing enterprise solutions, we understand your challenges and deliver customized solutions to help you overcome your unique business challenges.

OEE drives improvement by providing a better understanding of business losses and simplifying production issues. This helps you to make the right business decisions to increase efficiency and trim down operating expenses.

Implementing an OEE system will allow you to disrupt the operational data in your ERP system. In addition, you will be able to take your manufacturing operations to another level of production efficiency. To know more about how the implementation of an OEE system will help you enhance your business, talk to our experts.