The chemical industry is very diverse in nature, in all terms including products, processes, and assets. The industry converts natural gas and petroleum into intermediate materials, which range from small-scale speciality and performance chemicals to the large-scale commodity production of petrochemicals and basic inorganic chemicals. We rely on the chemical industry for a lot of products that we use daily; moreover, it serves as the backbone of many end-market industries such as construction, pharmaceutical, automotive, and agriculture. Industry 4.0 brings operational technology (OT) and information technology (IT) on the same platform and the chemical industry is one of the many industries which are being transformed by streamlining operations. Technologies such as the Internet of Things, additive manufacturing, machine learning, artificial intelligence, big data, and advanced analytics have reached a level where they can fundamentally be integrated with chemical companies to transform operations and develop new business models.

So what value does Industry 4.0 bring to the table for the chemical industry?

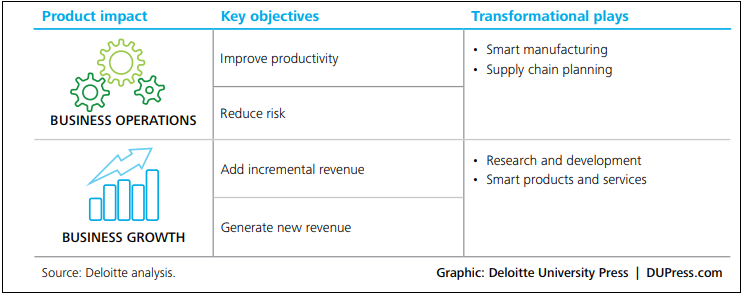

There are two major imperatives

- Business operations

- Business growth

Organizations that focus on business operations can put IIoT to work to improve productivity and reduce risk while organizations with more focus on business growth can use IIoT to explore new business models and build incremental revenue.

Since chemical companies have been collecting the abundance of historical sensors data over the years, business operations is one of the easy-to-target areas for digitization with IIoT. As shown in the above image, business operations can be improved in two ways – increasing productivity and reducing risk.

Increasing productivity

There are several smart manufacturing techniques with which productivity of a chemical plant can be improved: process control, real-time asset monitoring, predictive asset management, production simulations, etc.

Reducing risk

On the other hand, risk can be minimized by efficiently managing supply chain and in-house operations. With advanced data analytics, changing customer demands can be monitored while improving quality and safety.

Let’s see how digital transformation is possible with smart manufacturing and supply chain planning.

| Key objectives | Transformational plays and description | |

| Improve productivity Reduce risk | Smart manufacturing | Improve product quality with process management |

| Predictive analytics to minimize unplanned downtime | ||

| Smart energy management to cut on energy costs | ||

| Safety management by monitoring assets remotely | ||

| Production simulation to improve manufacturing planning | ||

| Supply chain planning | Demand forecasting to understand changing customer needs | |

| Monitor processes and people in real-time | ||

As the above table shows, chemical manufacturers can improve the productivity using various manufacturing techniques (supported by IIoT and machine learning): predictive analytics, production simulation, energy management, etc.

Now let’s learn more about smart manufacturing techniques in more details:

Predictive analytics to manage assets efficiently in the chemical industry

Be it batch or continuous manufacturing, efficient and high-yield production can be attained with smart process monitoring and management powered by IIoT. The biggest challenge is analyzing the asset data that is captured at different stages of the production process and then to make it available for useful decision support. Since the chemical industry is an asset-intensive industry, it is important to monitor critical equipment such as compressors, turbines, and extruders to predict and diagnose possible failures. This can be achieved by embedding sensors on critical equipment and collecting data from them, which can be of great help to plant operators to plan maintenance, get information about potential breakdowns, and manage parts ordering and delivery schedules. This will help companies to move from reactive maintenance to predictive maintenance.

Process management and controls

Gone are those days when operators in petrochemicals companies had to walk around in the control room to check readings to ascertain plant operations. Thanks to real-time analytics and rule-based control actions, companies can achieve future predictions, generate alerts based on certain critical events, and attain prescriptive responses. Smart process management helps operators to monitor the quality of the raw materials and variations in internal processes like temperature control, system fouling, raw material dosing, and so on. To achieve smart process management, companies need to collect data (both structured and unstructured) via sensors from various sources and build an ML model to identify deviations and patterns.

How Industry 4.0 is a game changer for factory owners

Webinar agenda

- How Industry 4.0 is a game changer

- The role of IoT and data analytics in the manufacturing industry

- IT/OT Convergence: Why it’s important for IoT adoption

- Current market trends and value

- Smart factory: The evolution not revolution

- Demo and review of smart production line monitoring

- Q&A session

Smart energy management

Who doesn’t want to reduce operating costs? To enable plant operators to select optimal operating conditions in order to reduce production costs, energy information should be made available for effective analysis to detect abnormal energy consumption patterns and quantify energy efficiency gaps. IIoT can help operators with monitoring of tank levels, flows, temperature and other critical parameters to derive optimal plant working conditions and minimize excessive energy usage while still meeting energy demand.

Safety management

It is critical to ensure the safety of workers in chemical plants. Use of wearables equipped with sensors will not only improve productivity but also reduce the risk of industrial accidents and health hazards. Data gathered from wearables can help detect abnormalities in physical conditions without relying on human decisions, which facilitates supervisors with safety management, health management, and labor management.

Production simulation

Today more and more companies are looking to improve worker experience with an aim to increase productivity. Companies have started building AR and VR applications for training operators and maintenance staff. Digital Twin is another emerging technology that bridges the gap between the digital and physical worlds in Industry 4.0.

Let’s take a look at supply chain planning techniques with IIoT:

Demand forecasting

Demand forecasting and responsive scheduling are greater ways to achieve capacity optimization. This can be achieved by deploying predictive analytics models and studying historical data that also includes external factors such as seasonal effects, regulatory changes, macroeconomic data, etc. With the help of demand forecasting, factories can identify demand indicators and adapt their plant runs as demand changes.

Monitor processes and people

The safe transit of chemicals and continuous monitoring throughout the supply chain is very important. There are certain products that need to be delivered within a specific range of temperature. Long range protocols like LoRaWAN can be used to ensure continuous connectivity and generate alerts in case of a collision. Companies can keep track of the location and send alerts to customers regarding the delivery status.

Opportunities are endless

Besides, there are many other areas where IIoT can create a huge impact and change the way chemicals companies operate and grow. If you are planning your Industry 4.0 journey and not sure how to integrate your physical assets with digital technology, then feel free to write us.